Mining engineers must utilize the optimization potential of geophysical methods in mining operations to explore the economic ore deposit, mitigate operational risk, enhance operational effectiveness, and secure project viability. Most mining projects crumble primarily due to this glaring oversight, yet the solution lies within reach. Geophysics is a tool that allows you to see the buried mineral deposit or a near-surface problem (geological or anthropogenic hazards) from a distance without drilling or excavation.

Your mining project doesn’t have to generate unnecessary expenses. With the intelligent integration of geophysics, it will become an efficient process that produces valuable results, empowering you with the tools and knowledge to make informed decisions and confidently drive your mining operations.

The role of geophysics in successful mining in a nutshell:

- Geophysics is integral to successful mining operations by helping you discover mineral deposits.

- Applying geophysical methods reduces many conventional mining risks.

- Geophysics aids in efficient and safer mineral extraction, increasing profitability and reducing environmental impact. It detects high-risk areas such as unknown subsurface voids, subsidence regions, or unstable rock masses before drilling and blasting begin. This aspect not only improves the efficiency of the extraction process but also reduces the potential for costly accidents or delays, thereby enhancing the operation’s overall profitability.

Why geophysics is a game-changer in mining

Geophysics is changing the mining industry, mainly when deeper ore deposits are the new and more frequent targets. Its importance becomes evident when you compare successful mining operations that use geophysics against those that don’t. For instance, an aeromagnetic survey mapped magnetic signatures of different lithotypes and significant structures in an Archaean granitoid-greenstone terrain associated with the world-class Kerr Addison orogenic gold deposit in the Abitibi Subprovince in Ontario, Canada. The first thing to remember is that mining isn’t simply about extracting minerals from the earth. It’s a complex industrial process that involves rigorous study and analysis to ensure sustainability and profitability.

Geophysical prospecting plays a paramount role in identifying mineral deposits. In the past, miners had to rely on surface indicators and manual labor to locate minerals. Today, geophysical tools can identify promising mineral deposits without drilling or digging.

Geophysics streamlines the locating process and reduces mining risks. Traditional mining approaches have numerous perils, including unsuccessful drill holes, potential ground surface collapse, hazardous gas leaks, and wasted resources in barren areas. Geophysical approaches reduce these risks considerably by delivering precise information about the ore deposit location and general structure, ensuring safer and more efficient ore resource estimation and mining operations.

How geophysics contributes to mining success

If you ask any mining executive about their top concerns, they’ll likely mention efficiency, productivity, and profitability. Mining projects that fail to employ geophysics often experience cost overruns, inadequate returns, and, in some cases, project failure. Contrarily, effective use of geophysics can significantly enhance both efficiency and profitability.

Geophysics aids in efficient mineral extraction. It provides a better understanding of the ore deposit architecture, translating to a more strategic excavation. The result? All minerals are included, and none are extracted wastefully. Not only that, but there are also significant time savings when using geophysics instead of conventional drilling surveying.

A study conducted in Brazil shows how geophysical methods yielded up to 77% in time reductions and a staggering 95% in cost reduction.

Additionally, geophysics helps mitigate the negative environmental impact associated with mining. Traditional mining processes can lead to soil erosion, deforestation, and water or soil contamination. Thanks to geophysics, a mining project can significantly mitigate harmful environmental effects by routinely monitoring the subsurface so that any potential contaminants are discovered early, and the extent of an impacted area can be mapped without the need for expensive preliminary drilling and soil sampling campaigns. Geophysics identifies the impact area by providing accurate subsurface information, ensuring that the extraction process is confined to where it’s most necessary.

Geophysical monitoring significantly boosts profitability by optimizing extraction efficiency and minimizing environmental impacts. For instance, it can identify subsurface instabilities caused by voids, sinkholes, and weak rock masses before heavy machinery arrives. These benefits create a compelling case for why mining projects should incorporate geophysics as a core component of their operations.

Mining geophysics accompanies you in all stages of the mine life cycle, as illustrated below.

| Mining Life Sequence | Activities | Potential Geophysical Applications |

|---|---|---|

| Exploration | prospecting, stripping, trenching, rock/soil sampling, geophysics, geochemistry, geology, drilling, resource estimate, environmental monitoring (soil/rock water/air), pre-feasibility studies |

|

| Consultations, permitting, engineering, and financial analysis | environmental assessment and monitoring (soil, rock, water, air) |

|

| Feasibility studies

(1-2 years) |

engineering, cost estimates, optimization, operating costs, reserve calculations, finding water, environmental monitoring (soil, rock, water, air) |

|

| Mine development

(1-3 years) |

site design, construction, exploration/development, environmental monitoring (soil, rock, water, air) |

|

| Mine operations

(10-30+ years) |

mining, mineral processing, smelting, refining, expansion, compliance, environmental monitoring |

|

| Closure, reclamation

(1-4 years) |

compliance environmental monitoring |

|

| Post-closure

(> 5 years) |

Reclamation and compliance with environmental monitoring |

|

Exploring deeper: geophysical methods used in mining

Each mineral deposit is unique due to its geological, mineralogical, geochemical, and geophysical footprint. Characterizing these footprints is the core of your exploration strategy. Some of the mineral deposits that you might have in mind might include Carbonate Replacement Deposits (CRDs), Porphyry Cu±Au±Mo, Epithermal Au-Ag, Mesothermal Au, Intrusion-related Au-Ag, Iron Oxide Copper Gold (IOCG), Volcanogenic Massive Sulfide (VMS), magmatic Ni-Cu-PGE, Uranium, and Diamond. Mineral deposits are explored using various techniques, including geological, geochemical, drilling (diamond and reverse circulation), and geophysical.

In mineral exploration, an anomaly is a geological, geochemical, or geophysical feature different from the surrounding non-anomalous rocks and may suggest economic mineralization. Interestingly, mineral deposits or ore bodies are anomalies, but not all anomalies are orebodies, so knowing how to distinguish them is quite a challenge. Dictated by its geological and mineralogical nature, an ore deposit will respond better to particular geophysical methods than to other methods. However, using more than one geophysical method might help corroborate the existence and footprint of a buried orebody. Detecting mineral deposits by geophysical means depends mainly on a single factor: the deposit displays physical or chemical attributes that differ significantly from the adjacent rock formations (i.e., host rocks).

Mineral exploration relies on measuring multiple geophysical properties over the target area; hence, each geophysical method uses a specific instrument to measure one physical property. The most important physical properties are density, magnetic susceptibility, electrical conductivity, chargeability, radioactivity, and seismic velocity (still undervalued). Therefore, the most common geophysical prospecting methods used in orebody exploration are:

- Gravimetry measures density in units of mGal or gu.

- Magnetometry measures magnetic susceptibility in units of nanoTeslas (nT).

- Electromagnetic measures electrical resistivity in units of Ohm-m.

- Electric measures electrical resistivity in units of Ohm-m and chargeability in milliseconds (msec), milliVolts/V (mV/V), or milliradians (mrad).

- Radiometric measures the natural radiation of gamma rays in units of % (K) or ppm (for U, Th).

- Seismic measures seismic velocity in units of m/s or ft/s.

Empowered with geophysical multi-method information, economic geologists and mining engineers can confidently navigate the terrain, fueling their success rates and setting the stage for profitable extraction. Combining some geophysical techniques makes up a powerful geo-toolbox that can exponentially improve the outcomes of any greenfield or brownfield exploration project or active mining operation. If you’ve been skipping geophysics, it might be time to reconsider.

Gravimetry method: weighing the possibilities

The gravimetry method measures slight changes in the Earth’s gravitational field, allowing us to weigh the possibilities in mining quite literally. Gravimetric surveys provide diagnostic information on variations in soil/rock density, permitting the identification of an excess or deficit of mass relative to the regional gradient. In mineral exploration geophysics, gravimetry helps delineate the footprint of ore deposits. Remember that varying thickness, density, or type of rock can cause changes in gravitational force, which are much better detected when noticeable density contrasts occur. Gravity surveys in mineral exploration measure differences in gravity between the survey stations and a survey station. Monitoring these fluctuations can lead to valuable clues to finding an ore deposit. Land gravity surveys are commonly conducted on the ground and airborne (fixed-wing airplanes and helicopters) and, in rare cases, in boreholes, and with satellites.

A geological or orebody model is subject to change, but geoscientific data is not. Complex geo-scientific data support a good ore deposit model. When combined with other geophysical methods, gravimetry becomes very effective, generating a 3D geological model. The NICO Au-Co-Bi-Cu (IOCG deposit) in northwest Canada is an example of a mineral deposit where the integration of high-resolution aeromagnetic, gravity, and deep electromagnetic data at deposit to regional scales with physical property measurements and geologic observations lead to a new understanding of the geometry of the deposit, adjacent mineralized and altered zones, and potential cogenetic links within the host metasomatic system.

In the mineral exploration industry, gravity surveying has the following applications:

- Regional mapping: mineralization/ore zone, lithotype identification, structural mapping, and target identification.

- Detection of several types of mineral deposits and some types of mineralizing environments.

- Delineation of large- and medium-scale geological structures.

- Characterization of the subsurface expression of igneous intrusions like granitic batholiths and massifs.

- Determination of ore tonnage by the excess mass method.

- Determination of the geometry of potential aquifers that might act as groundwater supply for mining operations.

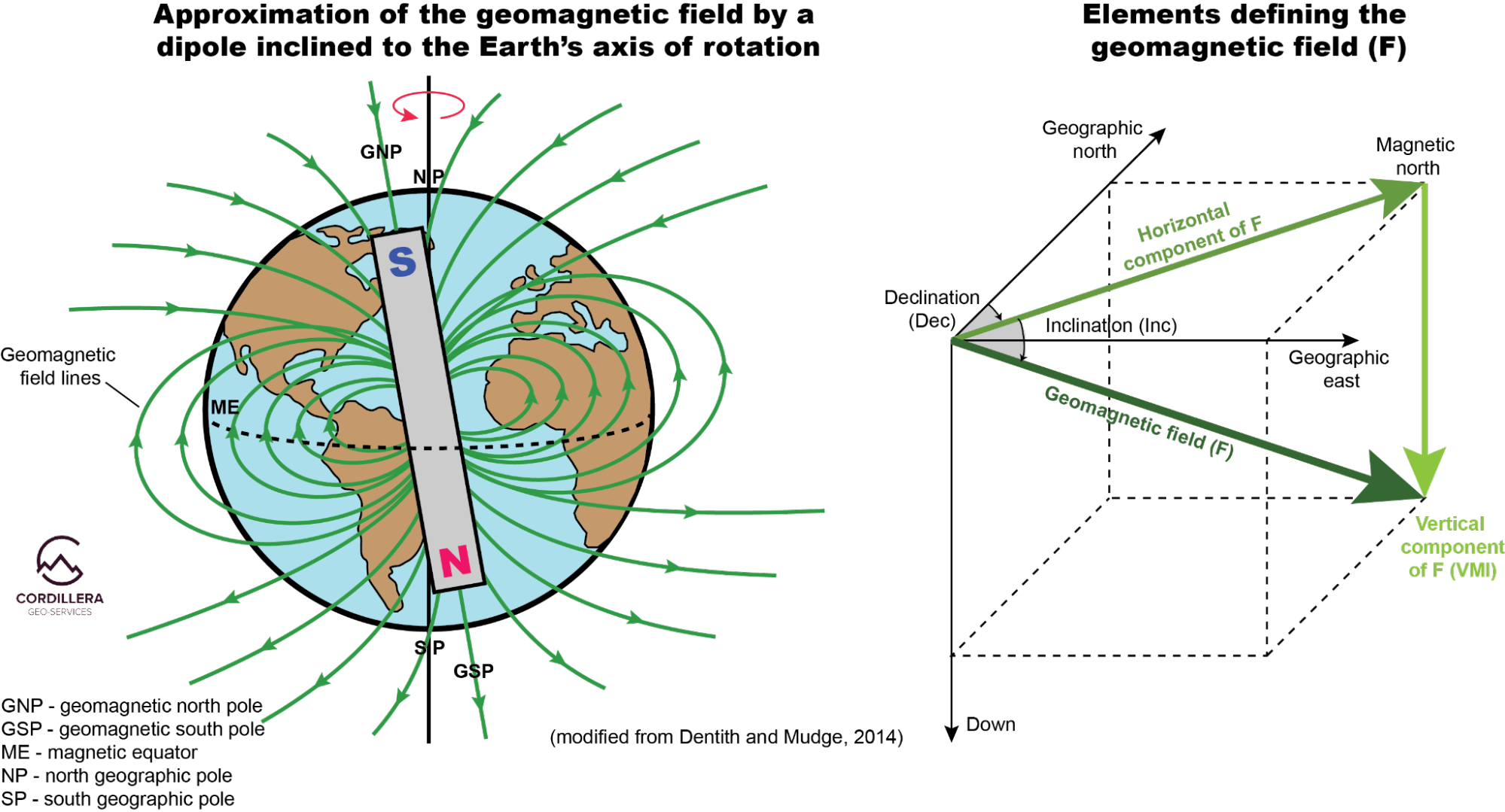

Magnetic method: attracting success

The magnetic method measures spatial variations in the Earth’s magnetic field due to magnetic materials (e.g., mineralization zones with magnetic-bearing minerals) in the crust that are of economic interest in mineral exploration. Certain minerals are naturally magnetic, and their presence can distort the Earth’s standard magnetic field. The strength of the magnetic field is measured and mapped in magnetic surveying. By measuring these distortions, geophysicists can pinpoint the likely locations of these valuable natural resources; this is why it is widely used in exploration campaigns. It is a widely used technique that detects magnetic anomalies that can signify economic ore deposits.

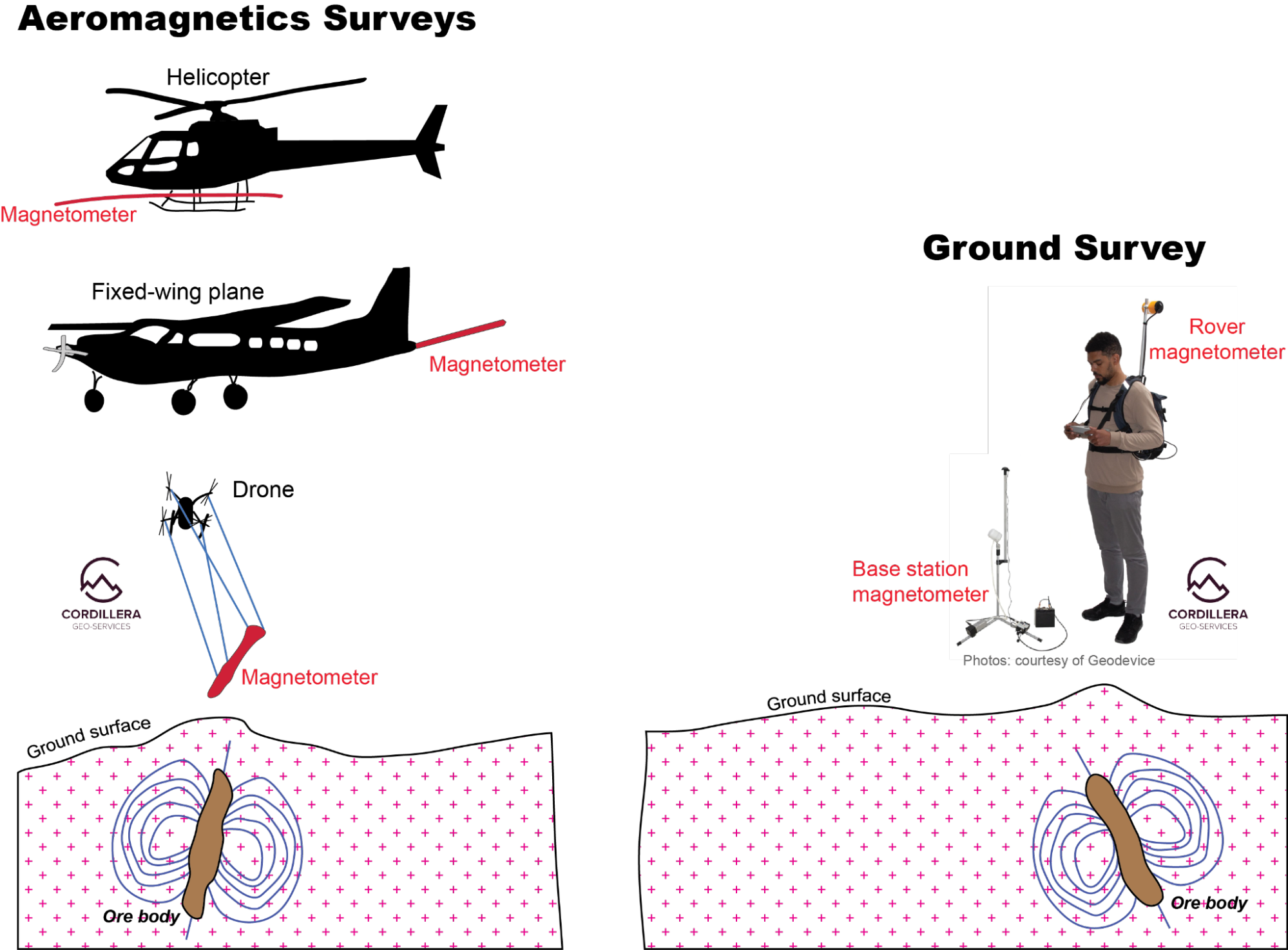

Magnetism is a vector quantity (magnitude and direction), causing magnetic anomalies to be dipolar. Absolute measurements of the total strength of the Earth’s magnetic field (the total magnetic intensity, TMI) are made from the air (in a helicopter or airplane), on the ground, and downhole with a magnetometer instrument. The magnetic field’s intensity decreases as the magnetic target’s depth increases. So, relatively shallower ore deposits or mineralization zones with ferromagnetic-bearing minerals yield stronger magnetic fields than if the same target was buried deeper.

Magnetic surveying is made on the ground, boreholes, and air. Magnetic surveying can significantly enhance a mineral exploration project’s success when implemented correctly. Aeromagnetic surveys are popular in mineral exploration for wide-area regional surveying, developing a geological framework, detailed prospect-scale mapping, and target detection. However, the degree of effectiveness depends on the type of ore deposit under investigation. In areas unimpeded by terrain and vegetation or poor rock exposure, aeromagnetics is an indispensable tool of exploration programs. Aeromagnetics can cover large areas faster at a relatively lower survey cost. The following factors are crucial in the design of aeromagnetic surveys: aircraft option (fixed-wing plane, helicopter, or drone), survey line spacing (10s to 100s m) and direction, survey flight height (100s m), type of flight (drape: for steep terrain; or barometric), and geological and logistical factors. Ground-based magnetic surveys can be done ‘on foot’ with the magnetic sensor mounted on the pole, ~2 meters above the ground, and a fixed-based station. Due to closer line spacings (e.g., 20, 40, 200 m), they offer much higher resolution.

Magnetic anomaly map products are also essential deliverables. For example, these include total magnetic field (TMF), reduction to the pole (RTP), the first vertical derivative of the RTP (RTP 1VD), the second vertical derivative of the RTP (RTP 2VD), tilt derivative (TILT), the horizontal gradient of RTP (RTP HzGrad), LowPass RTP (RTP LP), HighPass RTP (RTP HP). These magnetic anomaly maps are helpful for interpretation purposes. 2D magnetic modeling and 3D magnetic inversions are also beneficial; however, their restrictions must be considered. Though rare, downhole magnetic surveys find application in mining for delineating highly magnetic targets.

Even if the survey does not detect the presence of ores, the work done translates into savings because no further drilling occurs when barren areas are discovered. D.S. Parasnis famously said in his work Mining Geophysics that returns for every dollar spent in geophysics often come in hundreds and, in exceptional cases, even thousands.

Electromagnetic methods (EM): how to attract discoveries

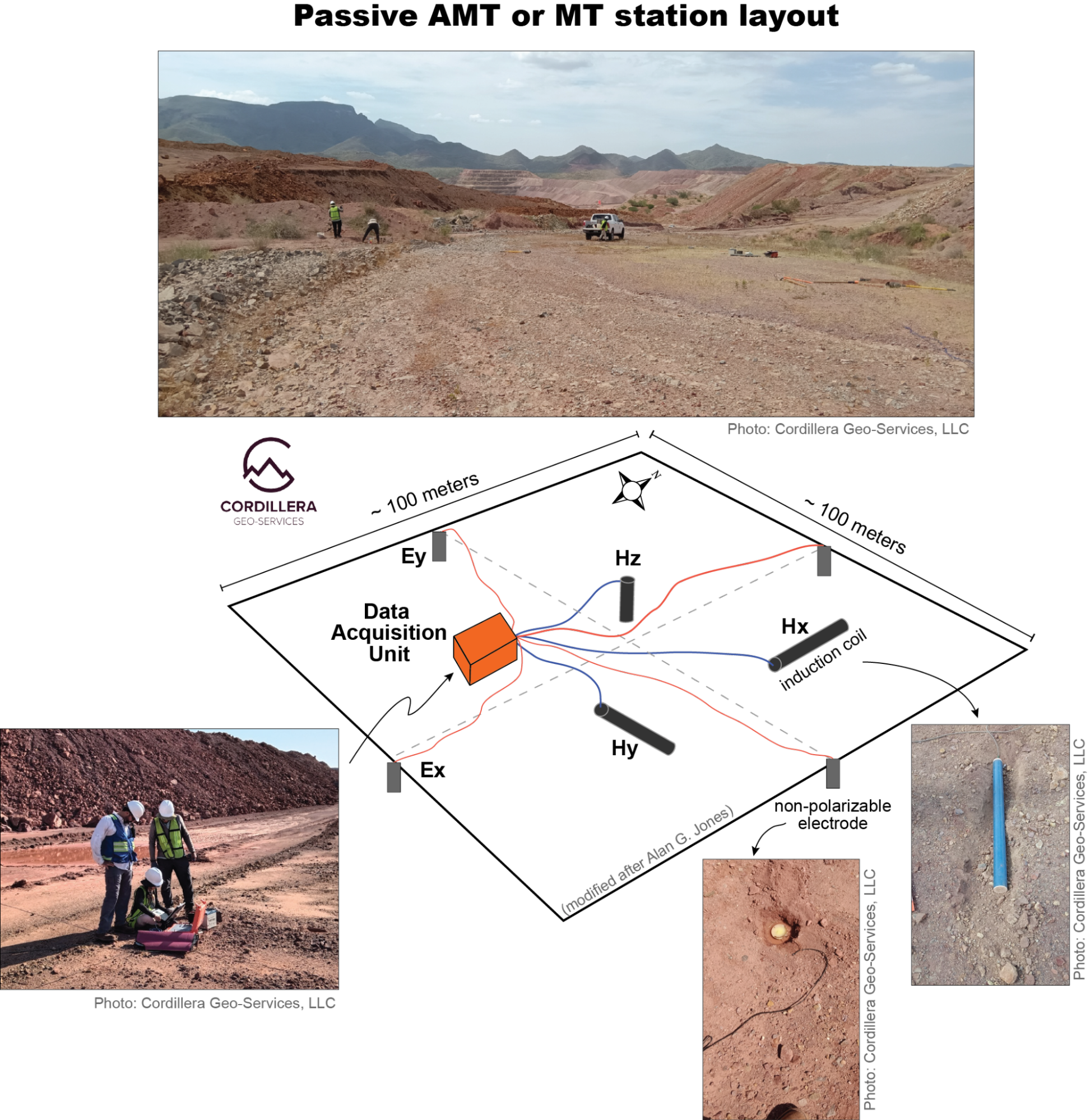

Electromagnetic (EM) methods measure the magnetic and electric fields associated with natural (passive EM) or artificially (active EM) generated subsurface currents. EM methods find buried electrical conductors or “conductive ore deposits;” however, the degree of success depends on the type of ore deposit being surveyed. Depending on the measured frequency range, EM methods offer a deep exploration depth, from 50 m to several kilometers. EM measurements are made in the ground, drill holes, and air.

Passive EM methods, such as Audio-Magnetotelluric (AMT) and Magnetotelluric (MT), employ natural incoming plane EM waves as the energy source. The EM waves are recorded by receivers or sensors. Passive EM methods are cheaper than active EM methods. The image below shows the layout of an AMT and MT station. Active EM methods require a controlled or artificial energy source (e.g., transmitter) and receivers; these include Transient electromagnetics (TEM) and Controlled-Source AMT (CSAMT). (CSEM). The CSAMT method requires a high-power transmitter that generates artificial EM fields with prescribed signal characteristics rather than natural EM fields. A CSAMT survey injects the current into the subsurface via a grounded horizontal electrical dipole antenna, making CSEM’s logistics more challenging. Both methods are excellent for mineral discovery; however, active EM methods offer higher-quality results because their measured induced signals are more potent than the natural signals measured in passive methods.

The applications of EM methods in mineral explorations include:

- Development of a regional geological understanding and direct targeting in most ore deposits.

- Identification of mineralization systems that yield conductive metals such as gold, silver, copper, zinc, nickel, platinum, iron, lithium, and uranium.

- Mapping of geological structures (shear zones, faults, fractures, folds), tectonic lineaments, volcanic sequences, and basement rocks.

- Gathering information about the depth and location of potential ore deposits to assist exploration drilling programs, reducing exploration costs.

If your target ore deposit is within the uppermost 1,000 m, then the ground-based passive AMT method is what you are looking for. If you want to know how to do an AMT survey, click here: How to do an AMT survey: deep geophysics. You can use the MT method if your target ore deposit is greater than 1,000 m. To see “How to set up an MT system: deep geophysics,” go here: How to set up an MT system: deep geophysics.

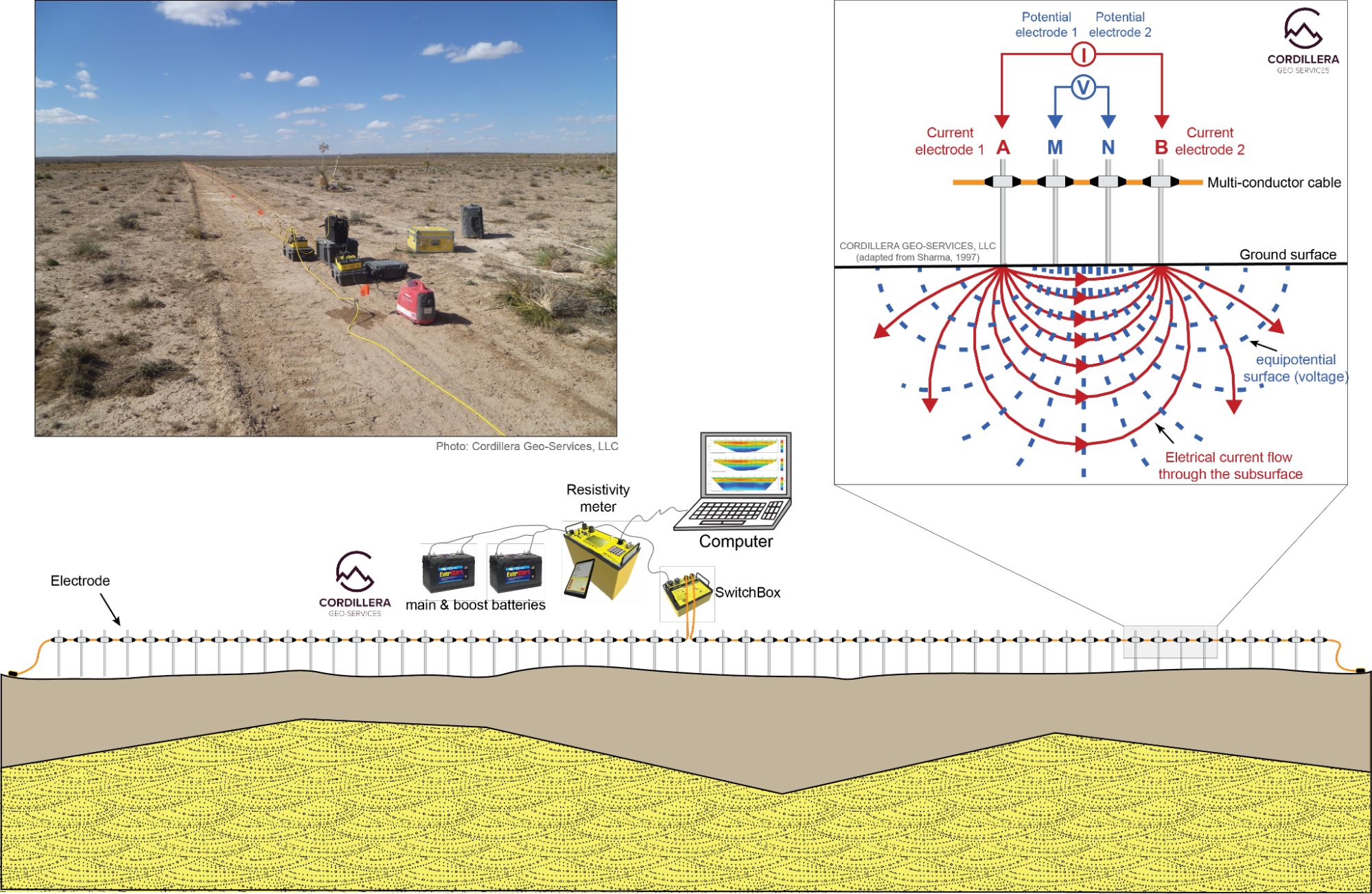

Electric methods: using electricity to find minerals

Electrical measurements of various types are made on the ground surface in boreholes to explore the potential of mineral deposits. Electrical surveying methods include direct current (DC) electrical resistivity, induced polarization (IP), and spontaneous-potential or self-potential (SP). DC electrical resistivity and IP are active, and SP is passive. All these methods can be made with the same instrument; however, non-polarizable electrodes are the best for the IP and SP measurements, while standard stainless-steel stakes are suitable for electrical resistivity measurements. The electrical readings are recorded using a precision electrical resistivity meter. The typical electrode arrays for mineral explorations are dipole-dipole, pole-dipole, pole-pole, and occasionally dipole-gradient to detect orebodies.

In electrical resistivity imaging, artificially generated electric currents are introduced into the ground with an array of electrodes pushed into the ground or in boreholes, and the resulting potential differences are measured at the surface with a second pair of electrodes, as shown in the image below. Lithology, mineralogy, pore fluid chemistry, clay, organic matter, and water content affect electrical resistivity.

IP imaging surveying is a complementary technique to electrical resistivity surveying, so you get two properties (IP and resistivity) in one reading. The IP method deals with the capacitance of conductive minerals in the subsurface materials, that is, the ability to store electrical current for a few milliseconds. When an injected electrical current passes through the subsurface materials, a small charge is stored, and the subsurface becomes charged. When the current is turned off, this injected charge gradually decays over a discrete time. This decay is seen in the recorded potentials at two potential electrodes. By measuring the rate of this decay, it is possible to calculate the chargeability distribution of the subsurface minerals/materials. Two materials that possess the same resistivity might have contrasting chargeabilities. Therefore, IP imaging can provide additional discrimination of subsurface materials.

The applications of the Resistivity/IP method in mineral exploration include:

- Mapping of coal seams.

- Identification of disseminated mineral deposits (gold structures)

- Detection of disseminated or veins wrapping around VMS.

- Discrimination between non-mineralized conductors (faults, shear zones, aquifers, etc.) and mineralized conductors.

- Mapping of alteration zones and structural features controlling mineralization (porphyry Cu systems).

The passive SP method is quick, cheap, and effective. The process is based on the surface measurement of natural potential differences (voltages) between a pair of buried electrodes resulting from spontaneous polarization in the subsurface, the sources of which are many and diverse: electrofiltration potentials, thermoelectric potentials, electrochemical potentials, and mineralization potentials.

The SP method can detect natural potential variations linked to metal sulfide, metal oxide, and carbonaceous mineralization. Sulfide and graphite orebodies, magnetite, coal, and manganese-bearing orebodies are sources of mineralization potential. These significant negative SP anomalies compete against background positive potentials generated by fluid streaming, geochemical reactions, biogenic, groundwater movement, and topography. SP anomalies are often interpreted qualitatively by looking at an SP map’s profile shape, amplitude, polarity (±), and contour pattern. The top of the orebody is thought to lie directly underneath the position of the measured minimum potential. Typical SP anomalies may have an amplitude of several hundred millivolts (mV) concerning barren ground. A resolution of 1 mV is sufficient for SP field measurements.

The applications of the SP method in mineral exploration include:

- Detection of disseminated and massive sulfide graphite, magnetite, anthracite coal, and manganese mineralization.

- Detection of sulfide mineralization/alteration in porphyry Cu systems.

- Delineation of geological features, such as shear zones, faults, fractures, and voids.

- Downhole SP measurements help identify changes in lithology.

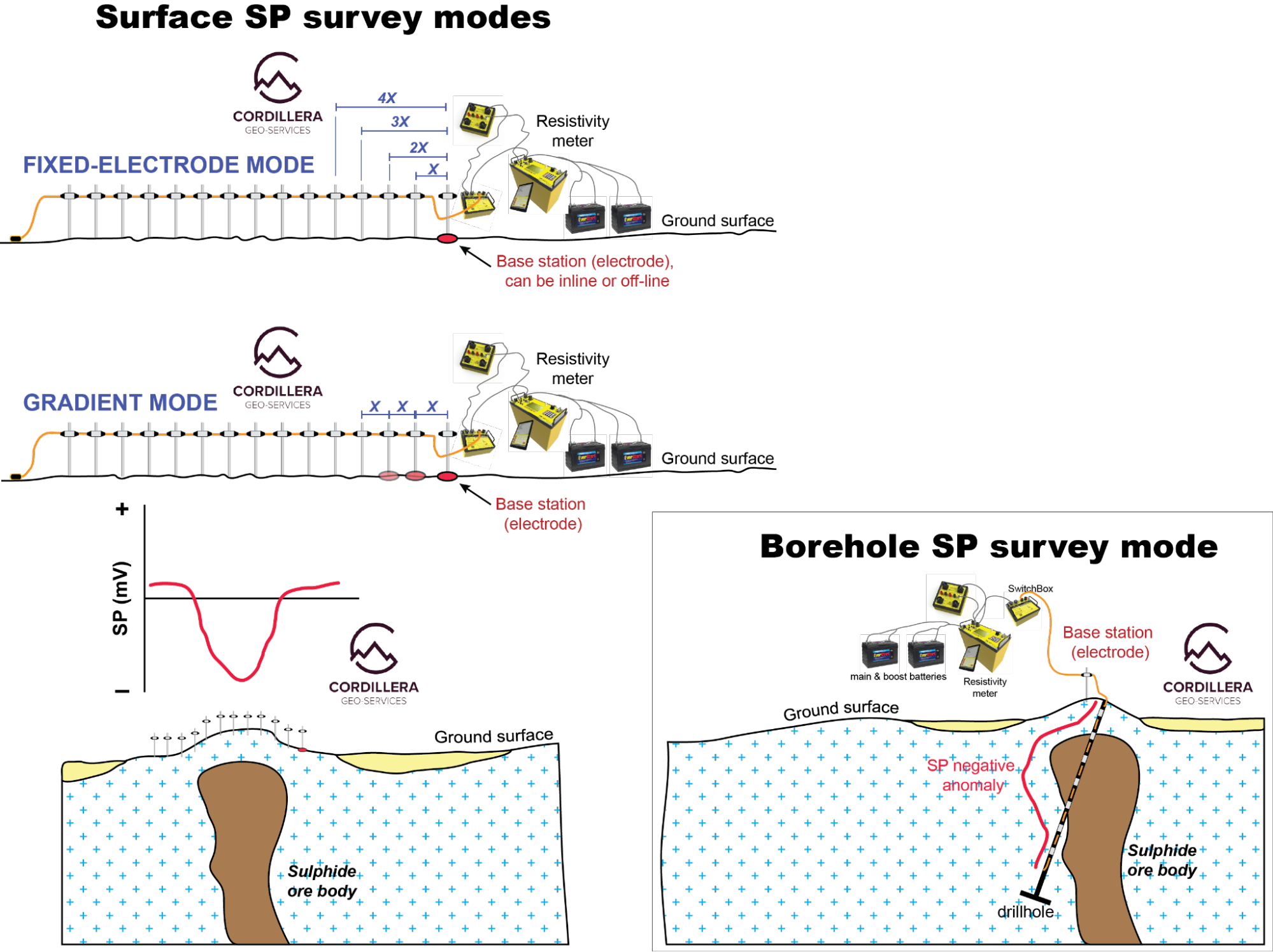

Field equipment consists of a pair of non-polarizing electrodes connected by an insulated cable, which in turn is connected to a precision high-impedance millivoltmeter with a resolution of at least one mV. SP measurements are made on the surface and in boreholes. Surface SP measurements are made with parallel profiles oriented perpendicular to the strike and spaced to suit the required resolution. Electrode spacing is typically less than 30 meters, and the penetration depth can vary between ~60 to 100 m depending on the orebody and the nature of the overburden. The surface measurement is made with one of two arrays: an SP-fixed electrode array or an SP-gradient array. The reference electrode in the fixed array can be inline or offline with the other electrodes. The reference electrode in the gradient array is only inline and moving along with the other electrode. The downhole survey uses the base electrode fixed on the surface, and the moving electrode moves inside the borehole. The image below shows the surface and borehole SP measurement configurations.

Radiometric method: detecting radioactive waves

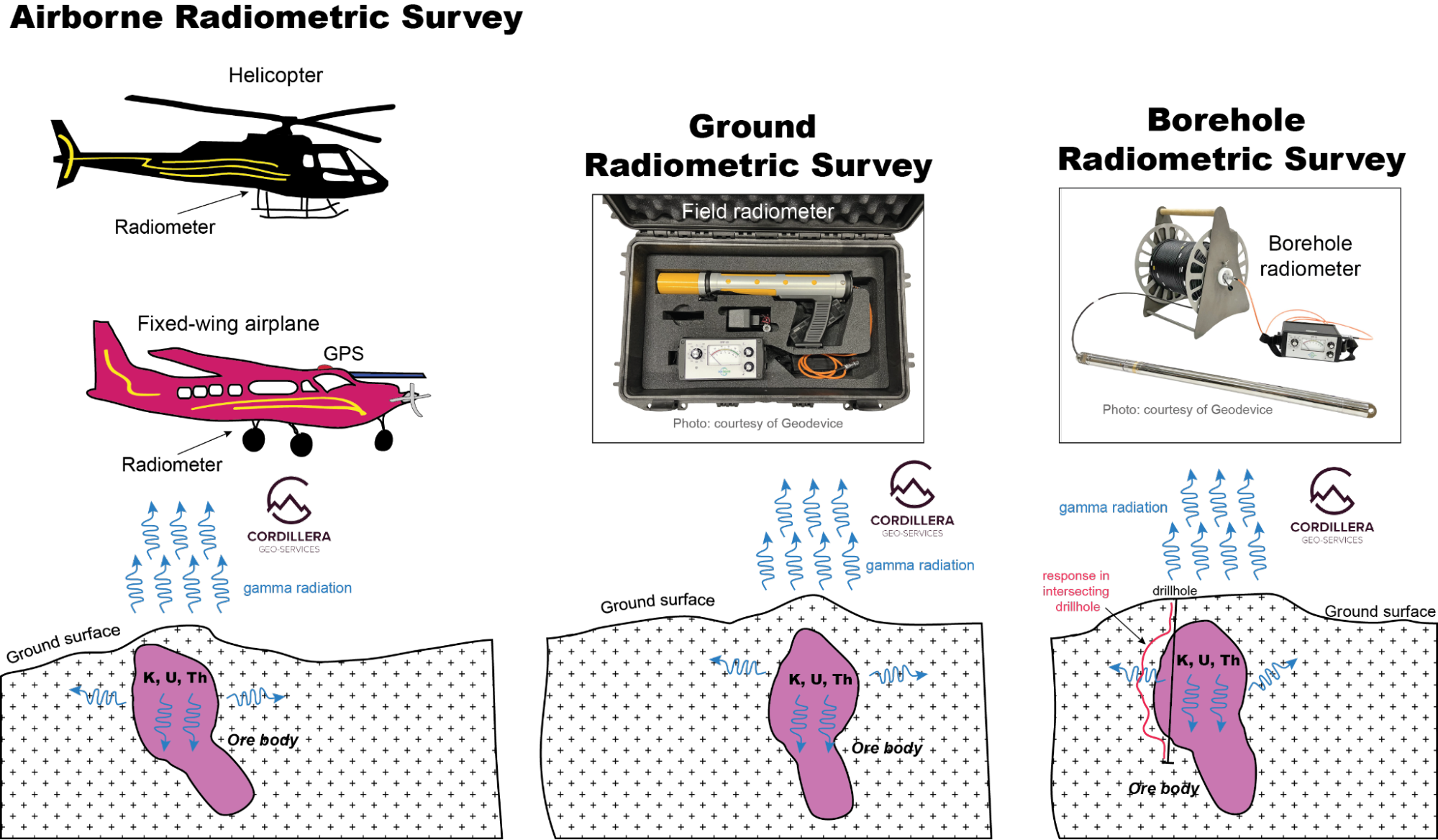

The radiometric method is a passive geophysical technique because it measures naturally occurring radioactive waves in the form of gamma rays released from the radioactive decay of uranium (238U), thorium (232Th), and potassium (40K). Radiometric surveying can detect absolute or relative amounts of U, Th, or K and is typically conducted on air, on detailed ground surveys with a hand-held radiometer, and in boreholes, as shown in the image below. However, it is ineffective in zones with high soil or overburden cover. This is because the gamma rays can only pass through a few centimeters of rock before being absorbed. It is common to add a radiometric sensor in an aeromagnetic survey. Mineralization itself, associated alteration zones, and favorable lithotypes for mineralization may all have anomalous radiometric compositions detected either in a particular radioelement or a specific ratio of the elements. Radiometric data are best interpreted with multispectral remote sensing data, digital terrain data, geological, drilling, geochemical, and other geophysical data.

The applications of the Radiometric method in mineral exploration include:

- Geological mapping and anomaly-detecting tools similar to magnetic surveying because the amount of U, Th, and K varies with each rock type; hence, changes in rock type lead to changes in the radiometric signature.

- Detecting uranium when exploring for IOCG.

- Mapping mineral deposits such as load gold, VMS, porphyry Cu, uranium, Olympic Dam type deposits, and Ni-Cu-PGE, to a lesser extent, from air to establish a geological framework and on the ground for direct targeting.

- Detecting mineralization itself, associated alteration zones, and favorable lithotypes for mineralization.

Seismic method: the Earth’s echo

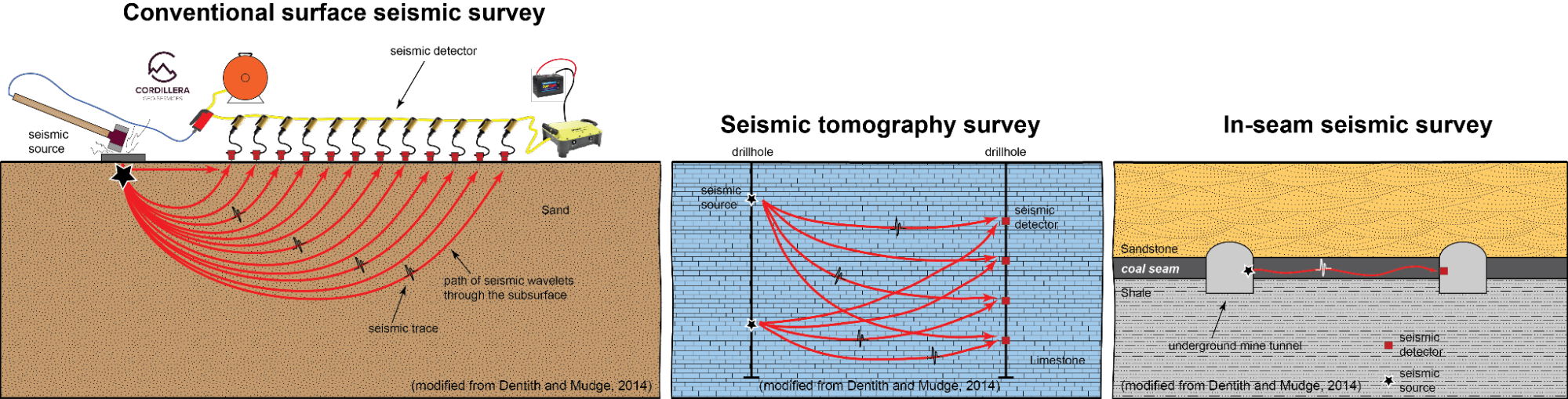

The seismic method is a critical geophysical player, working as the Earth’s echo. It is an active and passive form of geophysical surveying that utilizes the propagation of elastic (seismic) waves through the Earth’s layers to characterize the internal structure of a package of subsurface materials with similar or contrasting properties.

A passive (seismic microtremors, tremors, or earthquakes) or an artificial seismic source generates the elastic waves propagating through the subsurface before being recorded by sensors/detectors measuring ground deformation. The deformation of the ground as a function of time since the waves were created comprises a time series, which is called a seismic trace (a wiggly line). The passing of a seismic wave appears as a deflection of the seismic trace, referred to as a seismic arrival. The path from the source to the sensor or detector is determined by the material’s elastic properties through which they travel. Physical discontinuities in the elastic properties of the medium deflect and divide the seismic waves so that the detectors record a sequence of waves that have taken different travel paths through the subsurface. The nature and internal structure of the subsurface materials can be deduced by identifying these different arrival times and analyzing their travel times and amplitudes. In other words, by recording these seismic traces that represent ground vibrations, geophysicists create a picture of the subsurface, revealing the location of mineral deposits or potential hazards such as faults, fracture zones, sinkholes, subsidence spots, or cavities.

With geophysical crews meticulously surveying the ground, it’s estimated that mining projects using passive or active seismic methods are successful twice as often as those without, offering a significant return on investment. The metalliferous sector makes less use of the seismic method. However, its use is becoming more common, mainly because it is less suited for geologically complex settings where many types of ore deposits occur and its higher cost. The seismic reflection method is more expensive than the seismic refraction method; both are active and rely on body waves.

The seismic reflection seismic investigations have successfully helped image ore deposits in Europe, South Africa, and Canada with high resolution.

The engineering and environmental industries are frequent users of the seismic refraction method because they can investigate the structure of the shallow subsurface. The seismic refraction tomography method is a variant of the ‘refraction method,’ producing an image of the seismic velocity structure of the subsurface. Other practical seismic methods use ‘surface’ seismic waves to generate an image; however, their penetration is less than that of seismic methods using body waves.

The applications of the seismic method in mining have elevated the success rates of several projects worldwide. Different seismic methods exist, varying in size or scale, survey form, and the type of seismic wave each method measures. Alternative forms of seismic surveying used in the mining industry involve seismic sources and detectors deployed on the surface, with access provided by underground drill holes or underground workings, as shown in the figure below. Tomographic seismic surveys can map mineralization between drill hole intersections and are used for exploration at a prospect scale and during mining. In-seam seismic surveys use seismic waves intentionally guided through a coal seam to determine its characteristics before mining.

An active seismic case study: Europe, South Africa, and Canada

The reflection seismic method provided high-resolution images of structural and lithological relationships controlling mineral deposits in the Kevitsa Ni–Cu–PGE district in Finland, the goldfields of the Witwatersrand Basin in South Africa, and the Bathurst Mining Camp in Canada. This method permitted a better understanding of these regions’ architecture and ore-forming processes. 3D seismic data from the Kevitsa deposit yields an image of the 3D geometry of the ore-bearing intrusion and provides information about its relationship to the host rock units and nearby intrusions within a larger tectonic framework. 3D seismic data from the Witwatersrand Basin provided images of a significant, distinct reflector that acted as a marker horizon for the gold-bearing reef. 2D and 3D seismic data from the Brunswick area in the Bathurst Mining Camp suggest that the Brunswick horizon that contains massive sulfide and associated iron deposits occurs within a reflective package that extends down to at least 6–7 km depth.

A seismic case study: Cerro Colorado porphyry Cu-Mo deposit, Chile

A team of seismologists used local earthquake tomography to illuminate deep-seated, regional-scale structures that control the emplacement of porphyry copper deposits, the world’s primary source of Cu, Mo, and Re, in the upper crust. This discovery is important because such knowledge guides future mineral exploration in northern Chile’s Cerro Colorado porphyry Cu–(Mo) deposit. The result? They used the arrival times of body waves to construct a 3D model beneath this known Cerro Colorado porphyry Cu–(Mo) deposit extending to ~ 5–15 km depth. The model coincides with the surface expression of known porphyry copper deposits and prospects and delimits structures that host orebodies and related hydrothermal alteration zones. They deduced intermediate-felsic plutonic precursors for porphyry intrusions and mafic magma reservoirs that underlie shallower orebodies, respectively. Imaging these precursor and parental plutons with copper-bearing fluids will be pivotal to identifying orebodies. This investigation demonstrates the usefulness of local earthquake tomography as a tool to identify future deep mineral resources with minimal environmental impact.

How to conduct a geophysical survey for mining

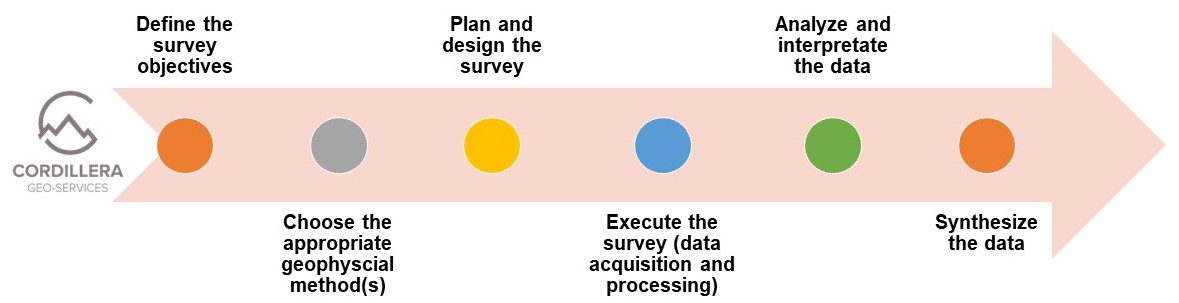

Carrying out a geophysical survey involves a series of systematic steps:

- Define the survey objectives: What do you want to achieve with the survey? Is it exploring possible mineral resources or identifying geological hazards?

- Choose the appropriate geophysical method: Methods could include gravimetry, magnetometry, electromagnetics, electrical resistivity, induced polarization (IP), spontaneous-potential (SP), radiometrics, or seismic. The selection of a technique depends on the survey objectives, the type of mineral deposit, and its associated geological context.

- Plan the survey: This involves choosing the survey area, determining the transect or grid layout, identifying noise sources, and deciding the exploration depth and resolution of the survey.

- Execute the survey: Skilled geophysicists and field crew use sophisticated equipment to collect and process data from rock formations.

- Analyze and interpret the data: This vital step transforms the raw and processed data into meaningful and actionable information that exploration geologists, mine geologists, and mining engineers can use for strategic decision-making.

Conducting a geophysical survey can avoid or reduce unnecessary risks and set itself on a trajectory to success.

Geophysics and mining sustainability: a greener future

Geophysics offers a non-invasive exploration approach that helps pinpoint mineral assets without excessive ground disturbance. Specifically, it identifies and helps quantify resources effectively, minimizing the need for indiscriminate mining.

Geophysics also contributes to sustainable water management, a key challenge in modern mining. By assessing groundwater reserves and monitoring water quality, project leaders can enhance the longevity of a mining site and its environmental compatibility.

Case study: Oyu Tolgoi

Rio Tinto’s Oyu Tolgoi Copper Mine in Mongolia is a shining example of sustainable mining powered by geophysics. The mine relied heavily on geophysics to accurately locate and quantify its copper and gold reserves. The result? They reduced their environmental footprint by focusing their efforts only where necessary. The mine also utilizes geophysics to monitor and manage groundwater.

Despite initially opposing sustainability, mining can be converted into an environmentally friendly process with the right tools and methodology. Embracing geophysics, a game-changer in the industry, sets miners on a greener path while securing the desired outcomes: optimal extraction with minimal damage, the promise of longevity, and sustainability.

Understanding mining geophysics: the basics

At its core, mining geophysics is a method employed within the mining industry to detect and map valuable subsurface resources like metallic and non-metallic ores and groundwater. It leverages technologies and principles similar to seismology, functioning as a non-destructive means of probing below the Earth’s surface.

Geophysicists, the key players in this process, can generate a picture of the subsurface geological features by deploying an array of geophysical instruments – ranging from gravity meters and magnetic sensors to electromagnetic, electrical, radiometric, and seismic survey tools. This aids mining enterprises in optimizing exploration drilling campaigns by pointing at where to drill, how deep, and how many, thus reducing the financial, logistical, and environmental costs associated with unnecessary exploration or excessive in-fill drilling.

The integration of geophysics into the mining industry took time. It traces back to the early 20th century when geophysicists began applying their science to the hunt for hydrocarbons and metals. Over the years, as technology advanced, so did the sophistication and precision of mining geophysics.

The 1930s saw an impressive evolution in mining geophysics, mainly due to the invention and use of sophisticated electrical and magnetic instruments. In the mid-to-late 20th century, developments in computer technology advanced data analysis and 2D and 3D modeling capabilities, providing a more accurate view of the earth’s subsurface. Time-lapse geophysical monitoring is still an underutilized technique, but it is a promising tool for continuous monitoring needs. Time-lapse geophysics is becoming an increasingly pivotal technique for measuring, monitoring, verifying, and predicting complex time-varying processes in the Earth’s interior. Technical applications in the mining industry include natural resource management (heap-leach irrigation monitoring, groundwater), geohazard risk assessment (slope stability, overburden stratigraphic changes, natural and induced seismicity), environmental issues (CO2 sequestration, groundwater contamination, and remediation), and geotechnical engineering (mine tailing dams, historical underground mine workings, slope stability). Geophysical methods adapted to time-lapse monitoring include but are not limited to gravity, magnetics, electromagnetics, electric (resistivity and IP), and seismic. For example, the impact of modern coal mining on overlying strata and its water-bearing conditions were determined with time-lapse multimethod geophysical surveying using 3D seismic, electrical, and ground-penetrating radar methods. The revolution in geophysical techniques continues today, progressively shaping the mining industry’s future. Depending on the process, some ground methods are becoming wireless.

The future of geophysics in mining

Mining for minerals is becoming more challenging because sizable shallow ore deposits are becoming difficult to find, making deeper ones the new targets. The mining industry continuously demands the improvement and development of technologically advanced geophysical hardware and software. Future applications may include more extensive and deeper remote sensing, machine learning algorithms for data interpretation, support exploration tools, and more environmentally conscious technologies. Despite the recent arrival of machine learning algorithms in geophysical exploration that employ available data to generate new ore deposit models, we must recognize that (new) geophysical data still needs to be collected and analyzed by traditional means. Hence, acquiring new geophysical data sets can only enhance the chances of successfully using artificial intelligence tools in mining exploration efforts.

What’s next?

The next phase in the evolution of mining geophysics may revolve around enhancing sustainability, reducing environmental impacts, and identifying geohazards. Geoscientists speculate that further developments, like advanced mapping of groundwater systems and predicting seismic activity, could significantly alter how the mining industry operates.

Conclusion: from data to knowledge

It is critical to understand that mining projects frequently fail in some stage of their mine life cycle due to undervalued or overlooked geophysics and the data that can be produced. Data is an undervalued commodity that yields information, which decision-makers transform into knowledge. Geophysics is the tool that allows you to see the invisible target (natural resource) or problem (geohazard or anthropogenic hazard) from far away. Mining geophysics can and should be integrated with other support tools that yield unique information, such as field geological mapping, geological logs from drilling, geochemistry, geochronology, geometallurgy, geotechnics, and environmental. It’s all about location, rigor-picking methods, and judiciously committing to interpreting data.

This knowledge can change the future of your mining project. With a solid foundation in geophysics, you’re equipped to navigate common pitfalls and edge ahead of the competition.

Prioritize geophysics in your upcoming mining venture. Don’t leave money on the table or below the surface. Let’s talk.