Safeguarding Drilling and Excavating: How Geophysical Surveys Prevent Disasters

Safety is paramount in the oil and gas industry. Yet, despite advances in technology and safety protocols, accidents involving gas lines during drilling, excavation, and construction continue to occur. These incidents often result from a need for more detailed subsurface information, a challenge that project managers, engineers, and safety personnel are constantly working to address, leading to unintended contact with gas lines.

The consequences of not conducting thorough shallow geophysical surveys before drilling or excavating can be severe. Past incidents in the U.S., where gas lines are accidentally struck during utility work, highlight the devastating effects of inadequate subsurface information. These accidents often result in loss of life, significant property damage, and costly legal repercussions.

Companies can avoid these tragic outcomes by investing in geophysical surveys. The upfront cost of these surveys is minimal compared to the potential financial and human costs of a gas line accident. This investment brings a sense of relief, knowing that the risk of such accidents is significantly reduced and reassurance that the safety of the team and the project is prioritized.

Geophysical surveys are noninvasive techniques that provide detailed images and data about subsurface conditions. Commercially available methods include seismic, gravity, magnetic, ground-penetrating radar (GPR), shallow electromagnetic induction, and electrical resistivity surveys to map the underground environment precisely. The geophysical data they produce is critical for identifying natural geological features and potential natural or artificial hazards that could pose risks during drilling and excavation.

How Geophysical Surveys Prevent Accidents

- Detailed Subsurface Mapping

-

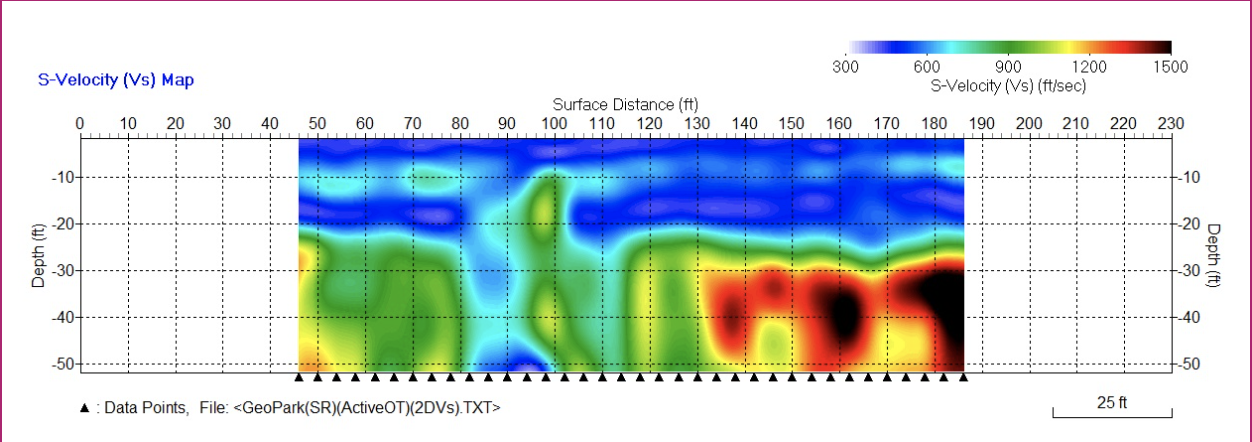

- Geophysical surveys create comprehensive maps of subsurface geology, allowing for the accurate identification of gas lines, faults, fractures, and gas pockets. This detailed mapping empowers project managers and engineers, giving them a clear understanding of the subsurface environment and the control to reduce the risk of accidentally hitting gas lines. For example, seismic surveys provide cross-sectional images of the earth’s subsurface, revealing potential hazards that could otherwise remain undetected, like the example shown below done with the 2D MASW (Multi-Analisis of Surface Waves) method.

- Gas Geohazards Detection

- Certain areas, such as continental shelves, are known for their gas geohazards. Studies have shown that geophysical surveys can effectively identify these hazards before drilling begins. For instance, surveys conducted off Iskenderun Bay revealed significant gas-related geohazards, underscoring the importance of pre-drilling assessments. By detecting these risks early, geophysical surveys allow for adjustments in drilling plans to avoid hazardous zones.

- Targeted Drilling

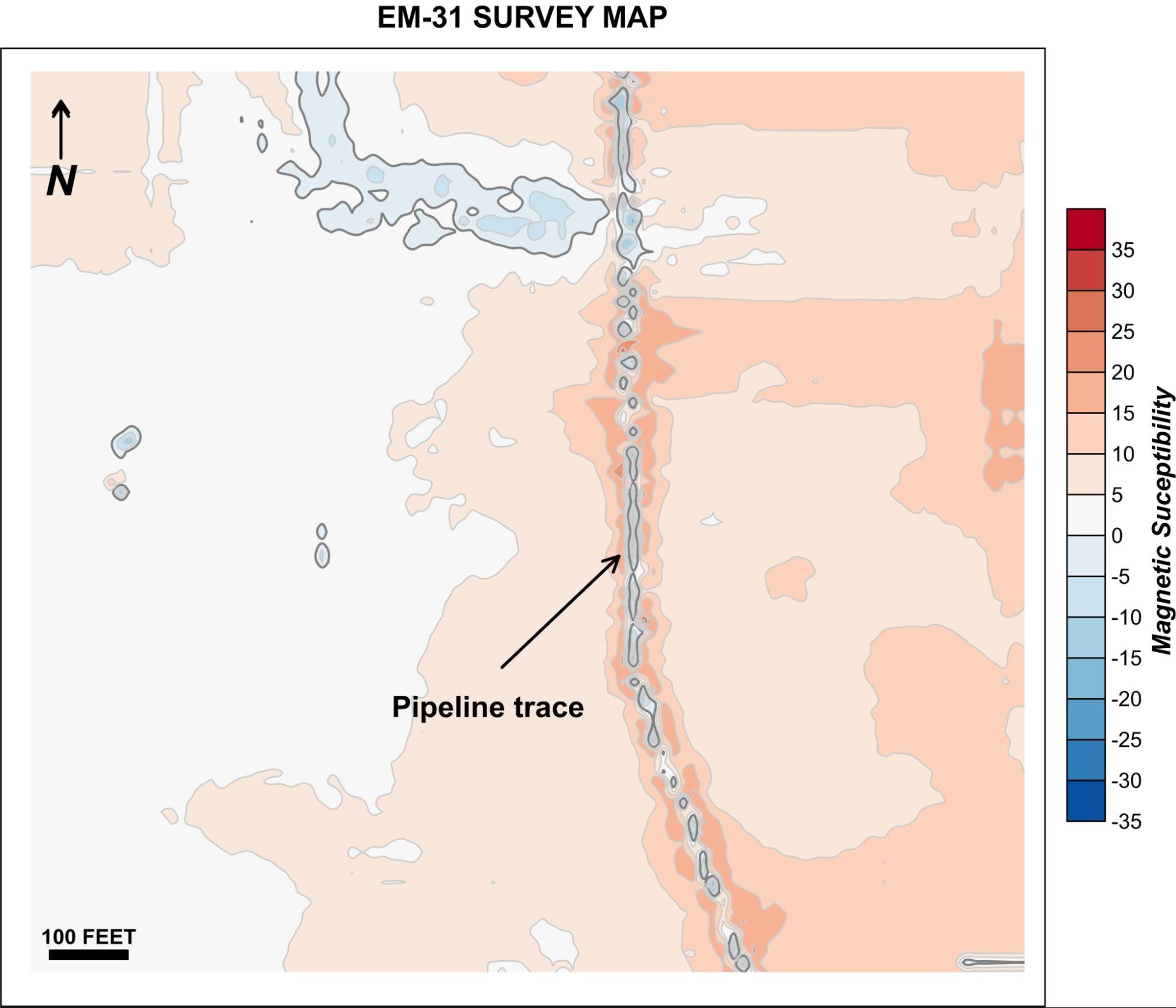

- The detailed information from geophysical surveys can help target drilling operations more precisely. This ensures that boreholes are placed in optimal locations away from gas lines, utility lines, or other potential hazards. Targeted drilling enhances safety and efficiency, reducing the likelihood of encountering unexpected gas lines or geological conditions that could lead to costly delays or accidents. For example, electromagnetic induction seismic surveys provide map view cross-sectional images of the earth’s subsurface, revealing shallowly buried gas lines. These potential hazards could remain undetected during environmental or engineering drilling or excavation, like the example below.

- Real-Time Monitoring

-

- Advanced geophysical techniques now allow for real-time monitoring of subsurface conditions during drilling. This capability is crucial for detecting sudden changes, such as gas influxes, that could signal imminent danger. By providing immediate data, geophysical surveys enable swift responses to prevent accidents, ensuring that potential threats are addressed before they escalate. For instance, many pipeline monitoring and oil leakage detection technologies exist and have been applied worldwide.

-

- Comprehensive Risk Assessment

-

-

- Geophysical surveys are integral to the risk assessment process in drilling and construction projects. By identifying geohazards such as gas pockets, subsidence zones, and unstable geological formations, these surveys allow for proactive risk management. Potential issues can be mitigated before drilling begins, reducing the likelihood of accidents and improving overall project safety.

-

-

Conclusion

Geophysical surveys are a recommended practice and a crucial safety measure that can prevent accidents during drilling and excavation. By providing detailed subsurface information, these surveys enable informed decision-making, targeted drilling, and effective risk management. In an industry where safety is paramount, geophysical surveys are critical in protecting both lives and assets.

By incorporating geophysical surveys into every drilling and excavation project, companies can ensure compliance with safety standards and proactive steps to prevent accidents before they happen.

Would you like to run a survey in your project to make better decisions? Let’s talk.